Table of Contents

Scaffolding is essential for an efficient, functioning workplace. It is vital to pick the right system to avoid overspending, improve safety, and have the correct type of scaffolding for the job. However, like formwork, there are many different types of scaffolds, and it may seem challenging to know which to choose.

A scaffold is a temporary structure acting as a stable, elevated platform for workers to engage in construction while also supporting the original structure. The type required will change depending on the structure and requirements.

Why Are There so Many?

Scaffolding is not a one size fits all product and should not be treated as such. It is not practical to choose aluminium over kwikstage on a large-scale construction site due to its limited load bearing. Similarly, you shouldn’t choose kwikstage on sites with little space on the ground floor when you can use a cantilever instead.

So why are there so many different types of scaffolding? Certain brands are superior, meanwhile, others are near identical.

Multiple factors are at play. The production capabilities of countries, access to raw materials and overall costs act as a barrier to specific systems. Workplace norms and culture also have an impact. If tradesmen use a certain scaffolding setup for a decade, it will take effort to convince them of the new structures and their merit.

There is the nature of the construction itself. Mobile and A-Frame offer similar benefits, but the latter may be chosen for its use of steel which is preferable on rough sites.

Types of Scaffolding

Below is a list of scaffolds currently in use today.

Suspended Scaffolding

Suspended scaffolding incorporates a platform held by cables suspended from above. Rigs either have stirrups or motors.

Key advantages include its lightweight build as the number of components required for greater heights remains the same compared to ground-based scaffolding.

The motor allows workers to adjust the height of the platform at their convenience, improving efficiency. It is the system of choice for highrise buildings requiring regular maintenance.

It does have downsides, however. Suspended scaffolding does not have the same freedom of movement horizontally as they do vertically. Additionally, they remain practical only on highrise buildings. Despite these drawbacks, they remain helpful for skyscraper repair works.

Trestle Scaffolding

Trestle scaffolds are supported by and move with tripod-like ladders. The tripod is their most significant advantage, as they are capable of self-support. Unfortunately, these contraptions are usually limited to indoor use, only reaching a maximum height of 5 metres. Builders can use trestles for painting and general repairs.

Cantilever Scaffolding

The cantilever is also known as a single-frame scaffold. Needles protruding from a wall support the standards; however, another variation involves the needles supported inside the floors through double frame scaffolds. The cantilever usually stands at an angle to the adjacent structure and is often located near balconies for ease of use.

A cantilever is beneficial on worksites where standard scaffolding is not practical. Instances include when the terrain is too uneven and unstable, or the working space on the ground is too narrow to fit.

A disadvantage of the system is the extensive inspections required for installation. Qualified scaffolders must be careful erecting cantilever platforms.

Single Scaffolding

One of the oldest methods in use is mainly used for brick masonry. This scaffold comes with standards, which connect to the structure’s wall at a distance of 1.2 metres and stand between 2 to 2.5 metres apart from each other.

Putlogs protrude from a gap in the wall to the end of a ledger in gaps of 1.2 to 1.5m, similar to ledgers.

As hinted in the name, this setup only utilises one row of standards. This limitation results in a weaker structure than other supports in this article.

Double Scaffolding

Like the single scaffold, the double counterpart is mainly for brick masonry. The setup uses additional standards to create a stable structure for working due to the difficulty of attaching putlogs to stone walls.

The standards closest to the wall are 20 to 30cm apart from it, while the second row of standards sits 1m apart from the first row.

Putlogs are held by ledgers on both ends of the scaffold instead of protruding from the wall. After the putlogs are positioned, further structural stability is supplied using cross braces.

The primary excuse for using a double scaffold over a single system is that it provides better support

Frame Scaffolding

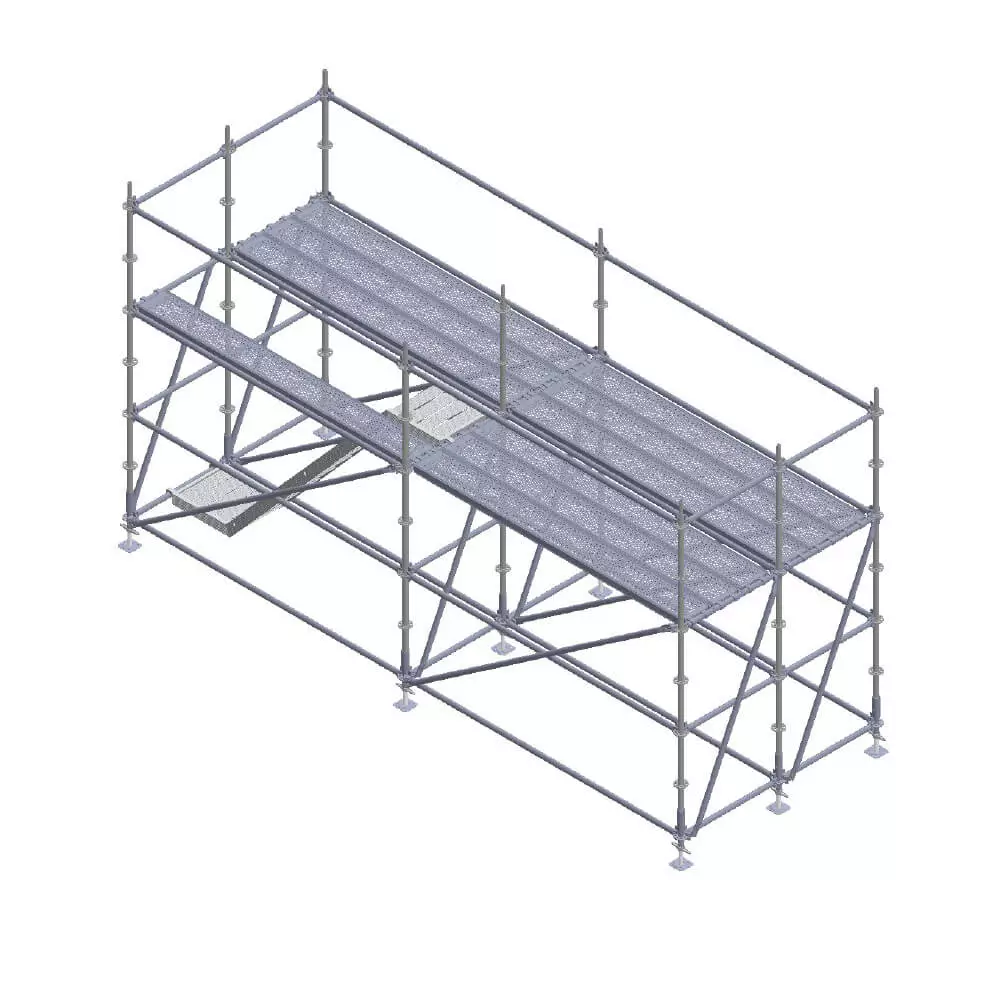

Referred to us as A-Frame scaffolding, it is a simple design that includes frames, braces, platforms, bases, and railing. It takes the portable nature of mobile towers and the strength of kwikstage and fuses them together. The end product is straightforward to assemble and offers greater load support over aluminium scaffolding types.

The image above demonstrates how construction workers can create portable or more complex systems with the frame design. The design is still only used on small-scale worksites.

Steel Scaffolding

One of the most popular designs on the market, steel scaffolding is created using steel tubes set by fittings or couplers. Long horizontal and vertical tubes hold together with the use of couplers where they intersect.

The steel on this type of scaffolding makes it predominantly for outdoor worksites. These systems offer easy assembly, increase on-site safety, strength, and fire resistance. A benefit of using this type is that there are fewer constraints and more freedom when working on irregular buildings.

The only downside is the high cost involved, whether by maintenance or labour for assembly. These issues are often overlooked given the benefits provided.

Modular Scaffolding

Modular systems are commonly used across the globe today. These types of scaffolding components lock together. Modular structures include many scaffold systems, such as:

Kwikstage Scaffolding

A popular choice in commercial construction, kwikstage scaffolding provides a safer and more robust platform to work on. Kwikstage uses galvanisation in the manufacturing process, creating a more durable platform that protects against the elements on an outdoor site.

The key benefit is the modular design that makes it easy to assemble and dismantle with its secure interlocking system.

Although an excellent choice, its use is limited to surrounding outdoor structures, and it lacks the portability of other varieties such as mobile towers.

Stair Access Scaffolding

The patented scaffold also uses steel but is ready-made. Once bought, they are ready for immediate use. Brackets support platforms and are set to be adjusted according to user requirements.

Ringlock Scaffolding

A relatively new scaffold structure, galvanised Ringlock employs a rosette on its standards instead of V-pressings. The rosette provides workers up to eight points of connection compared to the four offered on kwikstage.

Out of the different types of scaffolding in this article, Ringlock is the newest and least familiar to construction sites worldwide.

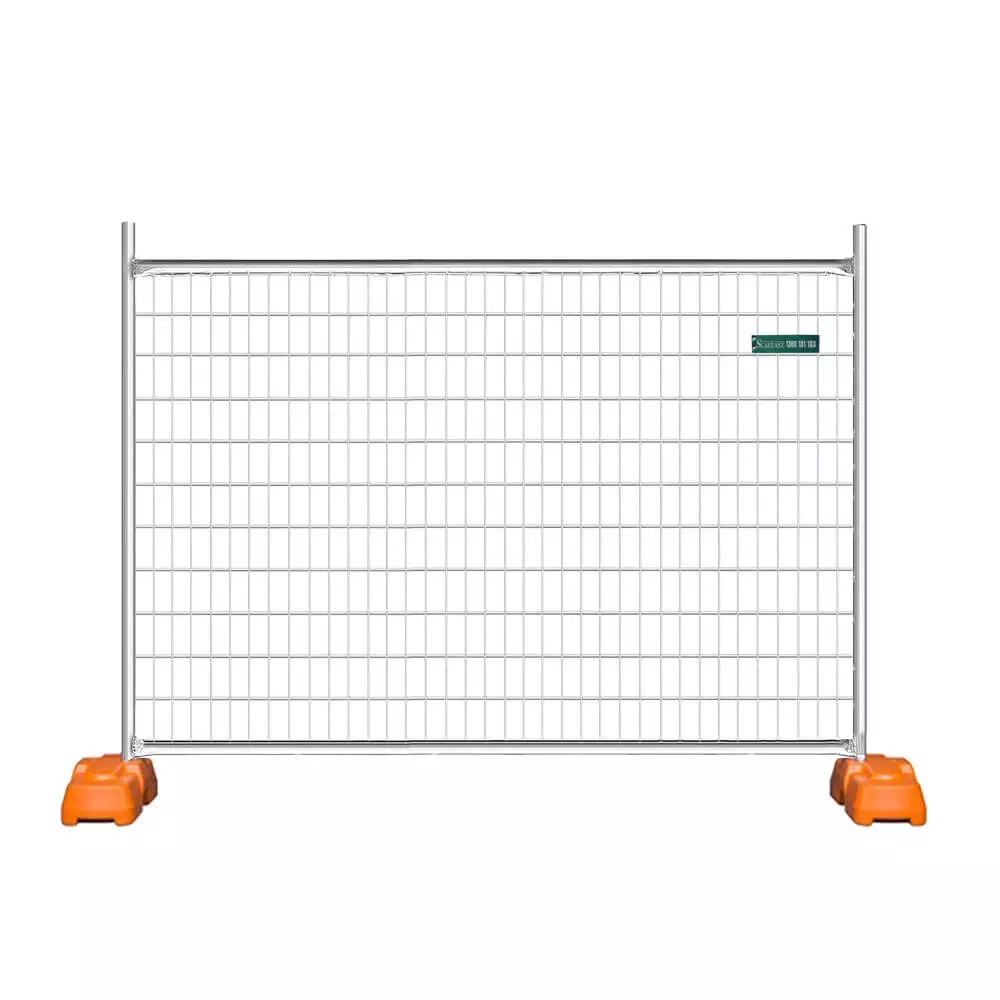

Mobile Scaffolding

Mobile scaffolds are known for their flexibility and portability. They include various sub-groups and are relatively new on the scene. Aluminium mobile scaffolds can come in sizes between 2 to 7 metres high and are appropriate for painting, general maintenance, or repairs.

There are also steel equivalents with many of the same traits, the key difference being a significantly larger safe working load.

The key benefits of these scaffolds are their ease of use and portability. The addition of caster wheels at the base allows towers to move around a site without dismantling. They are beginner friendly and scaffold maintenance is less work than Kwikstage or steel counterparts.

The main disadvantage is the lesser stability than other types and their smaller safe working load.

Mast Scaffolding

The exact opposite of suspended counterparts, mast scaffolding, extends up the face of a building under construction. The key difference is the trusses rising from the ground to support the working platform instead of cables overhead.

The setup means mast scaffolding is great on sites with little ground space. Support under the working platform allows it to hold heavier loads than its cable counterpart.

While it lacks the ability for horizontal movement, the use of traditional scaffolding parts allows workers to expand the platform further than what is possible on cable variants. This capability lets the structure bypass its previous limitation.

Looking to Hire or Buy?

If you are searching for kwikstage or mobile scaffolding, our team are here to help, and we encourage you to contact us at 1300 622 686.